|

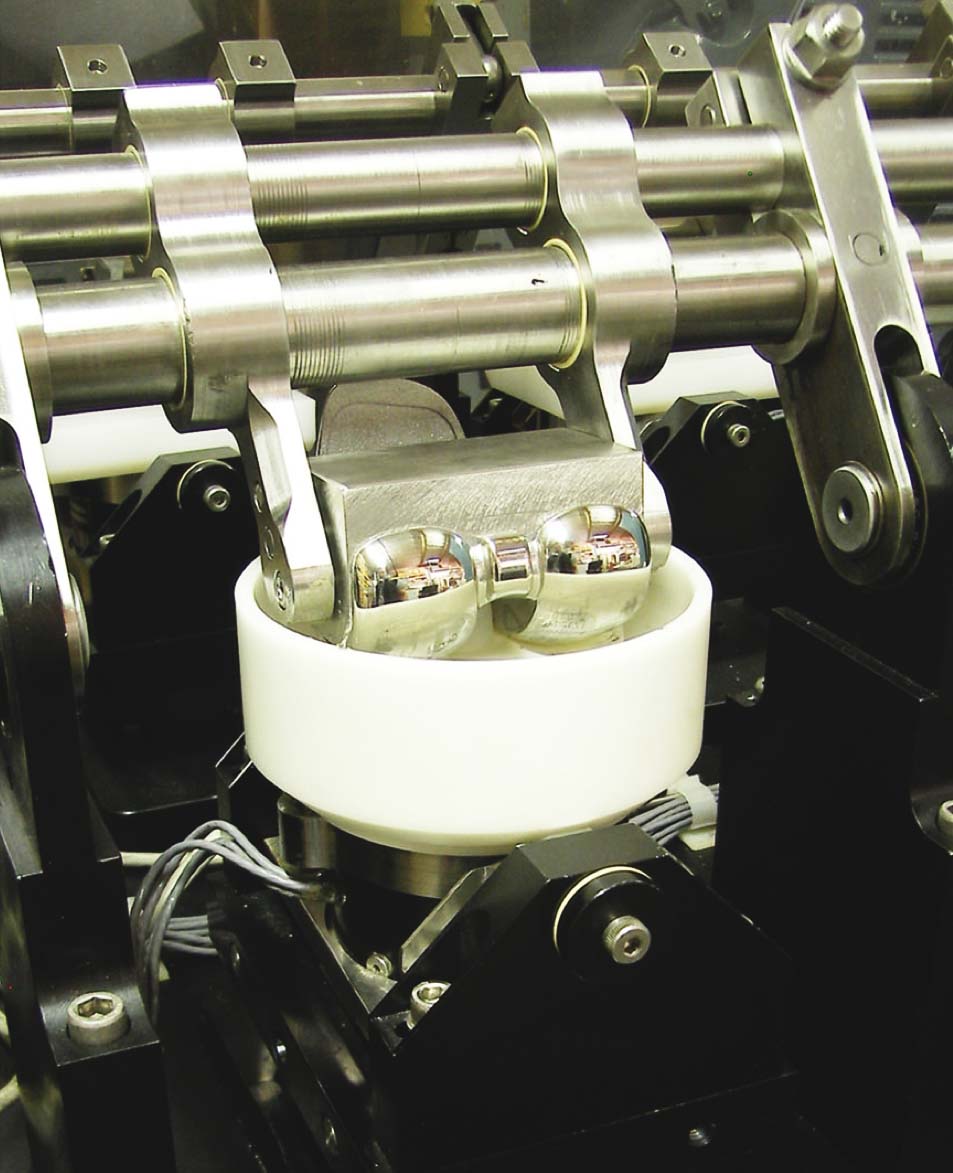

Knee Wear Simulator

|

Efficient and accurate ISO 14243 tests

The Shore Western Knee Wear Simulator was developed under direction of medical device manufacturers and orthopedic academics to simulate the complex kinematics and kinetics of the human knee in a physiological environment. Running in accordance with ISO 14243 axial load or displacement control, an array of knee complexities can be studied by researchers and designers looking to extensively analyze the mechanical properties and materials tribology of their prosthetic hip designs.

A typical knee simulator has six stations oriented in two series of three. Each station has the ability to run independently, with three controlled degrees of freedom: axial load, anterior/posterior translation, and internal/external rotation (axial torsion). Flexion/extension is applied across a set of three stations. Axial loads can be up to 5kN (1.1kip) per station, and femoral motion can rotate in the horizontal plane up to 140° (±70° flexion-extension). The simulator allows up to ±25mm (1in) of Tibial translation (anterior/posterior) relative to Femoral load, which is programmable to 735N (165lbs), combined with allowable internal/external rotation totaling ±10° for programmable loads to 36Nm (320inlb) about the vertical axis. The medial/lateral and Varus/Vulgus are both passive planes of motion with ±5mm (±0.2in) of translation and ±10° of Tibial rotation respectively. The medial/lateral pivot point is adjustable with ±10mm (±0.4in) of translation.

A typical knee simulator has six stations oriented in two series of three. Each station has the ability to run independently, with three controlled degrees of freedom: axial load, anterior/posterior translation, and internal/external rotation (axial torsion). Flexion/extension is applied across a set of three stations. Axial loads can be up to 5kN (1.1kip) per station, and femoral motion can rotate in the horizontal plane up to 140° (±70° flexion-extension). The simulator allows up to ±25mm (1in) of Tibial translation (anterior/posterior) relative to Femoral load, which is programmable to 735N (165lbs), combined with allowable internal/external rotation totaling ±10° for programmable loads to 36Nm (320inlb) about the vertical axis. The medial/lateral and Varus/Vulgus are both passive planes of motion with ±5mm (±0.2in) of translation and ±10° of Tibial rotation respectively. The medial/lateral pivot point is adjustable with ±10mm (±0.4in) of translation.Each knee joint is immersed in liquid (water, saline, or bovine/alpha calf serum), within an individual test chamber, making collection of spent serum for wear debris analysis straightforward, without risk of cross contamination between stations. Individual peristaltic pumps are available for each channel with level and temperature interlocks in each serum storage reservoir; lubricant temperature can be set and maintained via the heater/chiller unit. The test chambers are enclosed within polycarbonate swivel doors, maintaining a clean and safe test environment. Available loaded-soak stations (without knee kinematics) can accept three daisy-chained specimens on each load channel for a total of six. Each station includes independent control with load feedback.

Shore Western can also supply our industry acclaimed Whisperpak® hydraulic pump to complement the system. These pumps provide clean, full flow, conditioned oil at 210bar (3000psi) with less than 70dB of noise.