|

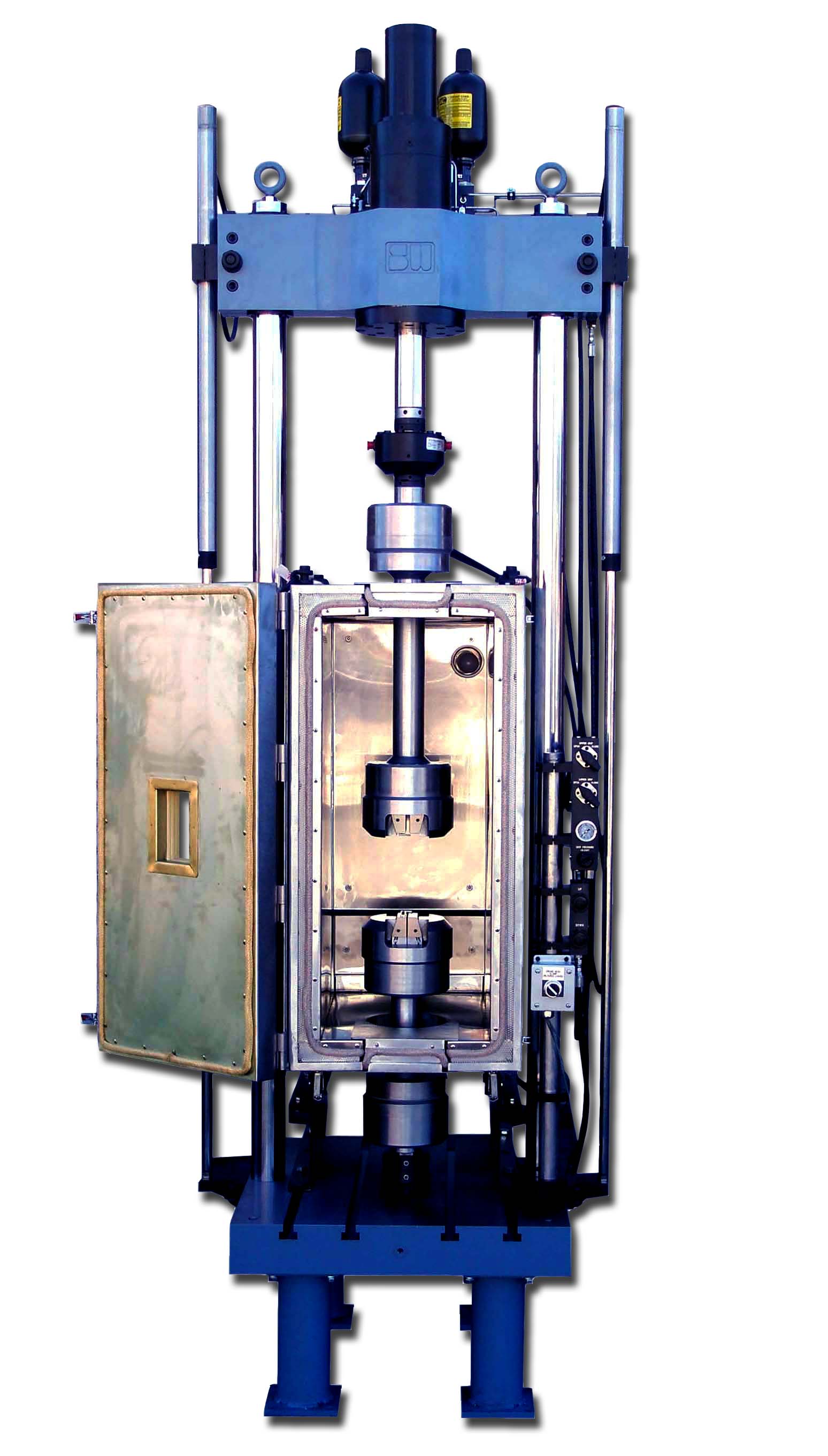

303 Series Loadframes

|

Our load frames are versatile test systems used for a variety of applications, from simple monotonic proof tests, to highly complex Thermo Mechanical Fatigue (TMF) experiments. The systems can be configured to run standard ASTM tests as well as unique custom protocols. The load frames are paired with our industry leading controller, and pumps to create highly accurate and durable test instruments.

The load frame structure is specifically designed to provide maximum rigidity, using high precision hydrostatic actuator bearings. The Series 303 load frames feature 2-column symmetrical construction with a fixed-platen and moveable crosshead on hydraulic lifts. On these free standing units, the actuator is mounted to a casting that can be mounted below the platen with the load cell affixed to the crosshead, or the casting itself can be used as the crosshead, so that the actuator extends from the top. A T-slotted base can add further flexibility for fixturing.

Note that we also build load frames with polymer bearings for a more cost effective solution (see our 302 line) and larger 4-column frames (see our model 304 frames). Our 301 series frames are tabletop units.

The 303 Series load frames come in standard configurations (see Specifications) with other force combinations and configurations available on request. All units are delivered fully equipped including a linear actuator, servo valve, service manifold, load cell, and LVDT.

The 303 Series Load Frame can be supplied with a variety of accessories such as hydraulic crosshead locks, load cells, grips, furnaces, environmental chambers, and extensometers to meet your specific testing needs.